Apple Recycles 20% of its Materials

Earlier this year Apple announced details of its material recovery initiatives to use more recycled content throughout its product range, including for the first time, the use of recycled gold, at the same time as increasing the use of other recycled materials such as tungsten, cobalt, and rare earth elements. The result of this material recovery plan is that almost twenty percent of the material used in manufacturing Apple products in 2021 was recycled.

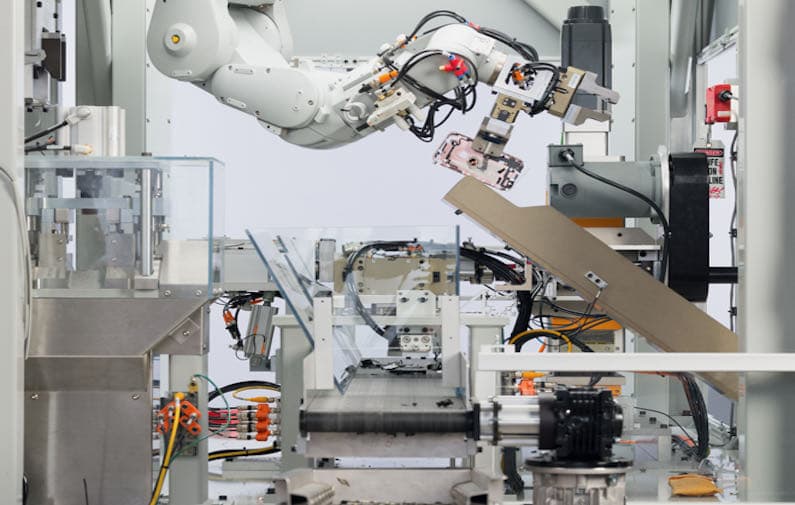

Apple’s Material Recovery Robots

One of the innovative ways in which Apple is reducing its consumption of raw materials is by designing robots that can break down its products to reclaim precious metals and other parts. Its first venture into this field was with the creation of Liam in 2016, a robot that could disassemble iPhones and break them into separate components. Liam was followed by an upgraded version, Daisy in 2018, capable of handling later models of the phones.

Daisy was followed by Dave designed to extract the taptic engine (used to create the buzzing feeling on the touch screen). Dave, in turn, was superseded by the most up-to-date model: Taz. Taz uses technology similar to that found in shredding machines, to recover more rare earth materials than previous robots, as well being able to recover the magnets from the audio speakers.

The net effect of these material recovery systems is that Apple is now using almost 60% recycled aluminum across the whole product range, with some products achieving 100% recycled aluminum. It has also reduced plastic in its packaging by 75 percent—a significant step towards its goal of being able to eliminate plastic packaging completely by 2025.

Saving Raw Materials

In early 2020 Apple announced that it is now achieving the following materials savings:

- 45% recycled rare earth elements.

- 30% recycled tin.

- 13% recycled cobalt (thanks to Daisy!).

- Major advances are also being seen in the use of recycled gold.

Material recovery savings such as these have a direct impact on the environment: for every ton of recycled gold and copper recovered, it would have been necessary to mine 2,000 tonnes of rock and ore.

Energy Efficiency

Product energy use accounts for 22 percent of Apple’s gross carbon footprint — and has an impact on the individual energy use of each of its customers. This is why the company has set aggressive targets to reduce its products’ energy usage. Apple approaches this challenge in the earliest phases of design, taking a holistic view of each product from how efficiently software operates to the power requirements of individual components.

With each generation of products, improvements are made to energy efficiency. The transition to silicon on Mac devices, for example, continues to drive these improvements — the Mac mini consumes up to 60 percent less energy while in active use than the previous generation.

Apple has also cut product energy use across all major product lines by more than 70 percent since 2008 through continuing energy efficiency improvements.

The progress Apple has made in reducing its impact on the environment shows just how much can be achieved with a dedicated approach to examining all aspects of the business, including consumer use of the products.

More information about Apple’s material recovery and environmental policies can be read in its 2022 Environmental Progress Report.

Recent Comments